This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Opto Control Tower

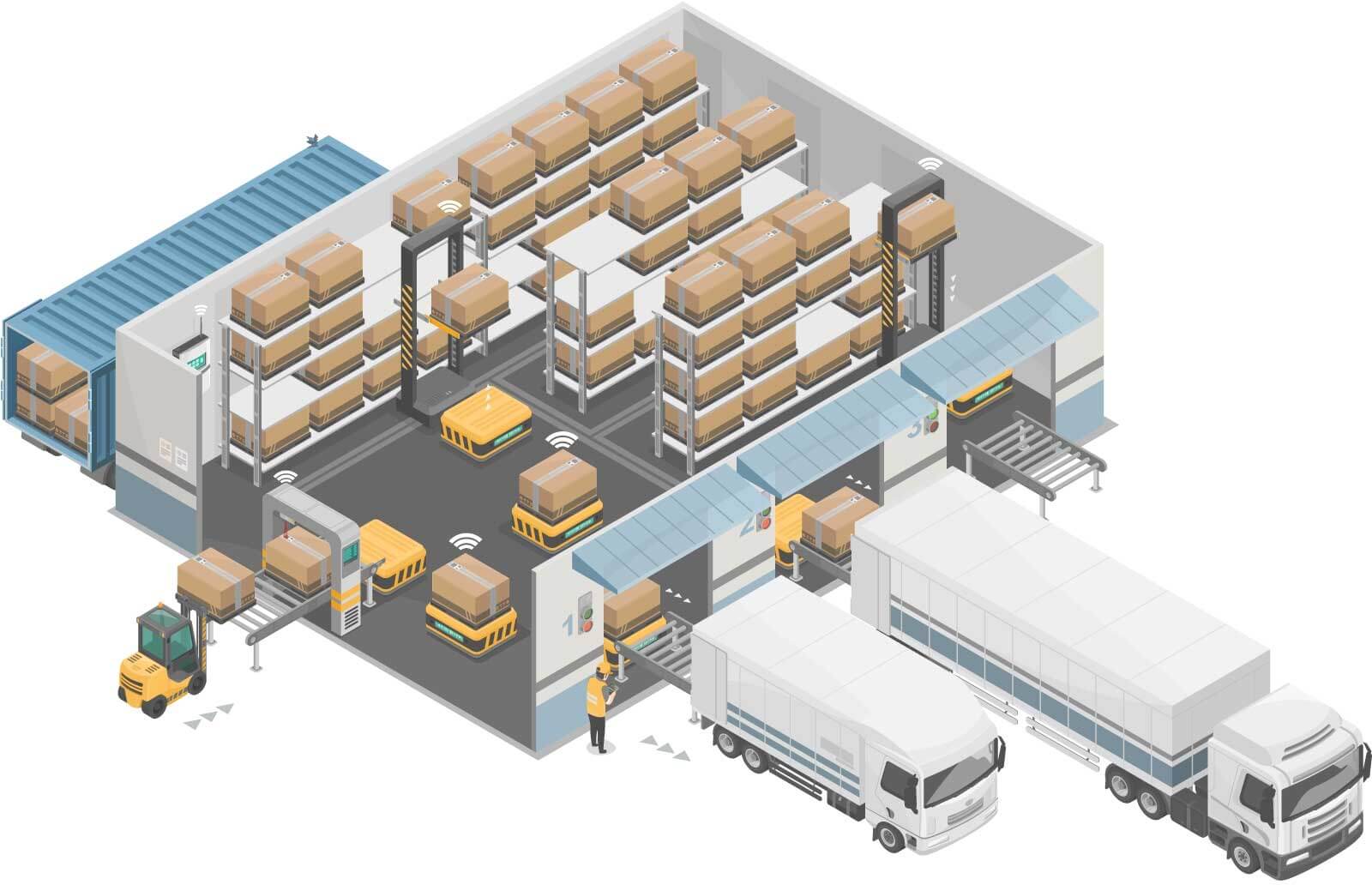

Opto Control Tower is a cloud-based solution that leverages advanced technologies – such as artificial intelligence, machine learning and the internet of things to proactively manage and optimize operations.

- Sensors (temperature, vibration, faults, energy consumption, etc.)

- Dock door scheduling/Yard management

- ERP systems

Operational Intelligence Platform

A graphical representation of the entire operation, incorporating predictive and prescriptive analytics to ensure maximum productivity.

A tool that can be used by any company, regardless of the system integrator, that allows users to see all key metrics and change the appropriate levers to increase the efficiency of the operation continually.

Opto Control Tower

Reports / Dashboards

Live Feeds / Visualization

Scenario Modeling

Equipment Health Monitoring

Network Analysis

Predictive and Prescriptive Analysis

Alerts

From War-Rooms to Analytics-Driven Decision Support

Intro to Control Towers

Control towers provide advanced visibility and analytics for the supply chain within 4 walls. They combine data from ERP and WMS coupled with automation data (Sensors and IoT) to allow continuous optimization.

Analytics-Driven Decision Support

Control towers can be used as analytics-driven decision support tools, connecting functions and interdependencies through visualization and dashboards. Improved control towers provide end-to-end connected insights for better decision making.

Real-Time Visibility and Actionable Insights

-

Operational Solution: Receives data from multiple operational workflows and can prescribe real-time changes/improvements.

-

From Visibility to Action: Captures, normalizes, connects data from sources to provide real-time visibility & analysis, then takes immediate actions.

-

Integrating with Systems: Integrates with any system for a granular and prescriptive view, sold individually.

See

- Provide visibility into how long dock doors are in use

- Provide visibility into all operational areas of a warehouse/DC

- Provide visualization effects as well as live camera feeds throughout the operational areas

- Provide one location where clients with multiple projects (buildings) can view all projects’ key metrics for comparison

Tell

- Provide alerts into when operational events exceed configurable thresholds. For example, if a dock door is open longer than a configurable # of minutes.

- Provide alerts when equipment exceeds configurable thresholds (i.e., temperature, vibration, etc.)

Understand

- Provide advanced analytics into operational processes

- Provide predictive analysis prior to errors/faults occurring

- Provide interactive tool for operator to make changes based on advanced/predictive analytics (instead of requiring operator to login to source system to make the change)