This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

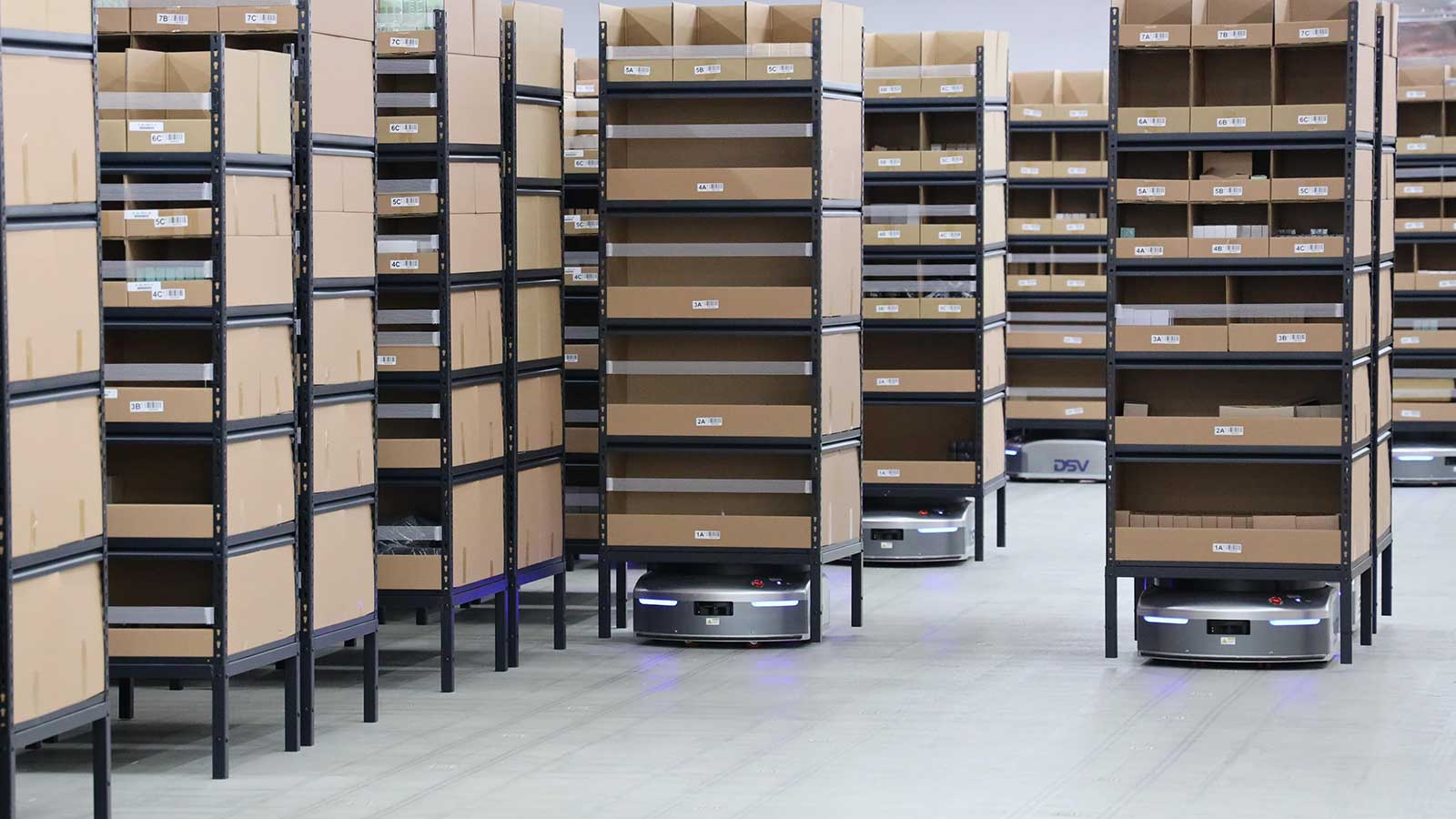

Automated Mobile Transportation is a Necessity

Employee resources are limited. Using valuable staff to perform low-value tasks, like material transport, is a costly and inefficient way to do business. The use of automated mobile transportation vehicles, such as autonomous robots, in a warehouse, distribution center, or manufacturing facility to transport goods and materials within the facility have become a necessity.

Automated Mobile Transportation

Automated mobile transportation systems can increase efficiency, reduce errors, and lower costs. They can also be integrated with other technologies, such as inventory management systems and automated picking and packing systems, to create a highly efficient and streamlined operation.

-

Increased Efficiency: Move goods around the facility faster and more efficiently than manual labor, reducing the time needed to complete tasks and improving overall productivity.

-

Improved Safety: Risk of accidents involving forklifts or other manual handling equipment can be minimized, creating a safer working environment for employees.

-

Costs Savings: Reduce labor costs and improve the utilization of warehouse space, as the vehicles can work continuously without the need for breaks or rest periods.

-

Higher Accuracy: Programmed to move goods with precision, ensuring they are placed in the correct location and reducing the risk of errors that can lead to delays or damaged goods.

Goods-to-Person AMR Picking Systems

- Reduce the time required to fulfill an order, increase productivity, and minimize the risk of errors or accidents.

- Can be programmed to move between storage locations and picking stations and can even transport items between different areas of a warehouse, distribution center or manufacturing facility.

- Reduce labor costs by automating repetitive tasks, allowing workers to focus on more complex or higher-value tasks.

- Reduce risk of worker injury by performing tasks that may be physically demanding or require workers to operate heavy machinery.

Benefits of AGVs and AMRs

Increased Productivity

Reduced Operating Costs

Create Flexibility

Decrease Damage & Improve Safety

Enhanced Inventory Control

Scalable Throughput

Mobile Automation instead of Fixed Automation

Outdoor Network

Ten Geek+ autonomous mobile robots (AMRs) transport 75 carts of oversized items to static shelving and pallet rack for putaway, and move oversized picks in carts to a consolidation area for outbound shipping.

“The technology makes our pick and pack process so simple.”

– Warehouse Manager, 3PL Provider

How and Where Are Automated Mobile Transportation Technology Used?

- Regular delivery of stable loads

- Medium throughput and volume rates

- Processes that critically require on-time deliveries and accurate material tracking

- Frequent, repetitive movement of materials over a distance