Automation Delivers Agility, Capacity, and Resilience

In today’s consumer-driven marketplace, the ability to quickly and successfully adapt to rapidly changing demands, variable product mixes, and shifting inventory volumes can be a competitive differentiator. By adopting today’s automated technologies, a company can gain a level of agility, capacity, and resilience not possible with manual or conventional operations.

How Automation Increases Operational Agility

Driven by intelligent software that continuously analyzes inventory availability and order profiles, today’s automation perpetually slots and re-slots stock-keeping units (SKUs) based on popularity. This action ensures a proactive, agile response to shifts in demand.

Likewise, overarching warehouse execution software (WES) synchronizes and orchestrates fulfillment through various automated technologies. With the right WES, an operation can leverage multiple automated equipment options while eliminating siloed automation. By unifying flow across best-of-breed materials handling and robotic equipment, a process can more easily adapt to changing situations, such as an unexpected order spike.

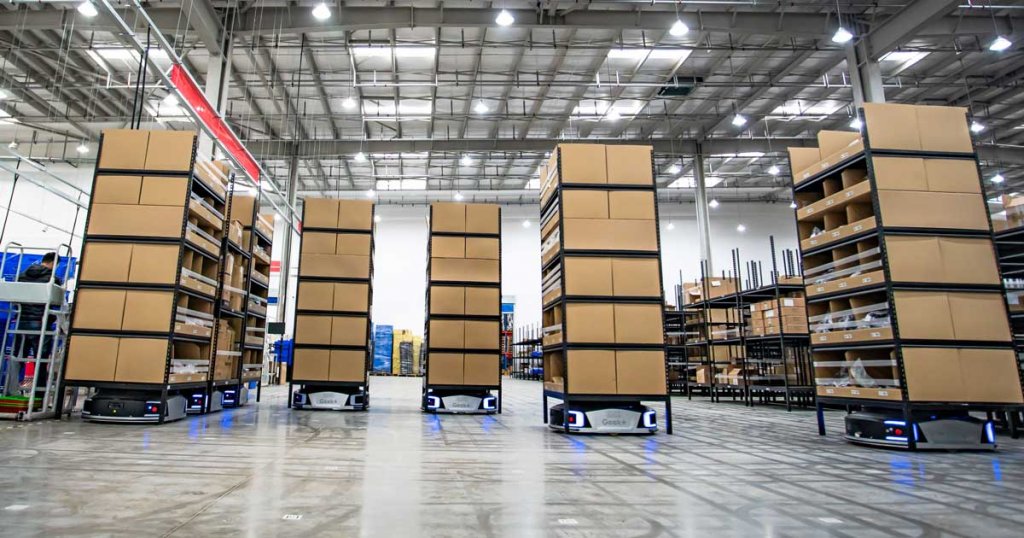

Finally, today’s automated solutions, like autonomous mobile robots (AMRs), are significantly more agile and scalable than traditional automation—such as fixed conveyors or sorters. Current automation options have little or no immovable infrastructure and can be reconfigured much more quickly than fixed assets. This process allows a company to deploy more AMRs as needed to accommodate seasonal variability, shifts in order volumes, and more.

How Automation Boosts Storage and Throughput Capacity

With the increasing popularity of online shopping, customers have come to expect a virtually unlimited breadth of choice. Not having an item in stock can result in a lost sale. Yet a facility’s three-dimensional storage capacity is finite, and additional square footage carries a cost.

Adding an automated storage and retrieval system (AS/RS), such as a high-density cube-based system, can significantly increase a facility’s storage capacity. These solutions are built as high as possible to maximize the cubic density of the building in a reduced footprint. Unlike static racking, they eliminate the need for travel aisles and clearances, enabling an exponentially more significant number of SKUs to be held within the same square footage.

Additionally, an AS/RS design considers periods when order volumes spike significantly. Some peaks occur seasonally; others happen daily. Informed by analysis of an operation’s order and throughput data, automation can be scaled to create a right-sized solution that accommodates variable demand. Further, AS/RS systems can assist with slotting products so faster movers are more readily available for picking.

How Automation Supports Operational Resilience

Today’s companies are eager to find solutions that help their DCs quickly adapt and respond to disruptions and business upheaval. With automation, a company can increase operational resilience via:

Greater network adaptability. Operations can quickly respond to disruptions caused by weather, port strikes, or pandemics by shifting inventory and fulfillment processes to other automated facilities in their supply chain network.

Less reliance on labor. With automation handling simple inventory movement and repetitive or dangerous tasks, the impact of turnover and absenteeism is lessened. Further, employees can collaboratively work alongside robots or be reallocated to higher-value work.

Reduced training time. Jobs supported by automation are often easier and faster to learn, allowing new employees (or temporary labor) to become proficient and productive quickly.

Improved ergonomics and safety. Automation makes jobs more manageable and less strenuous by reducing bending, lifting, reaching, stretching, and more. This reduces the risk of injuries and worker’s compensation costs.

Looking to start your automation journey? With a custom-engineered automated solution, KPI’s experts can help your operation gain agility, capacity, and resilience. Contact us today.

Categories (tags):