This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Maximizing Efficiency in the Protein Industry

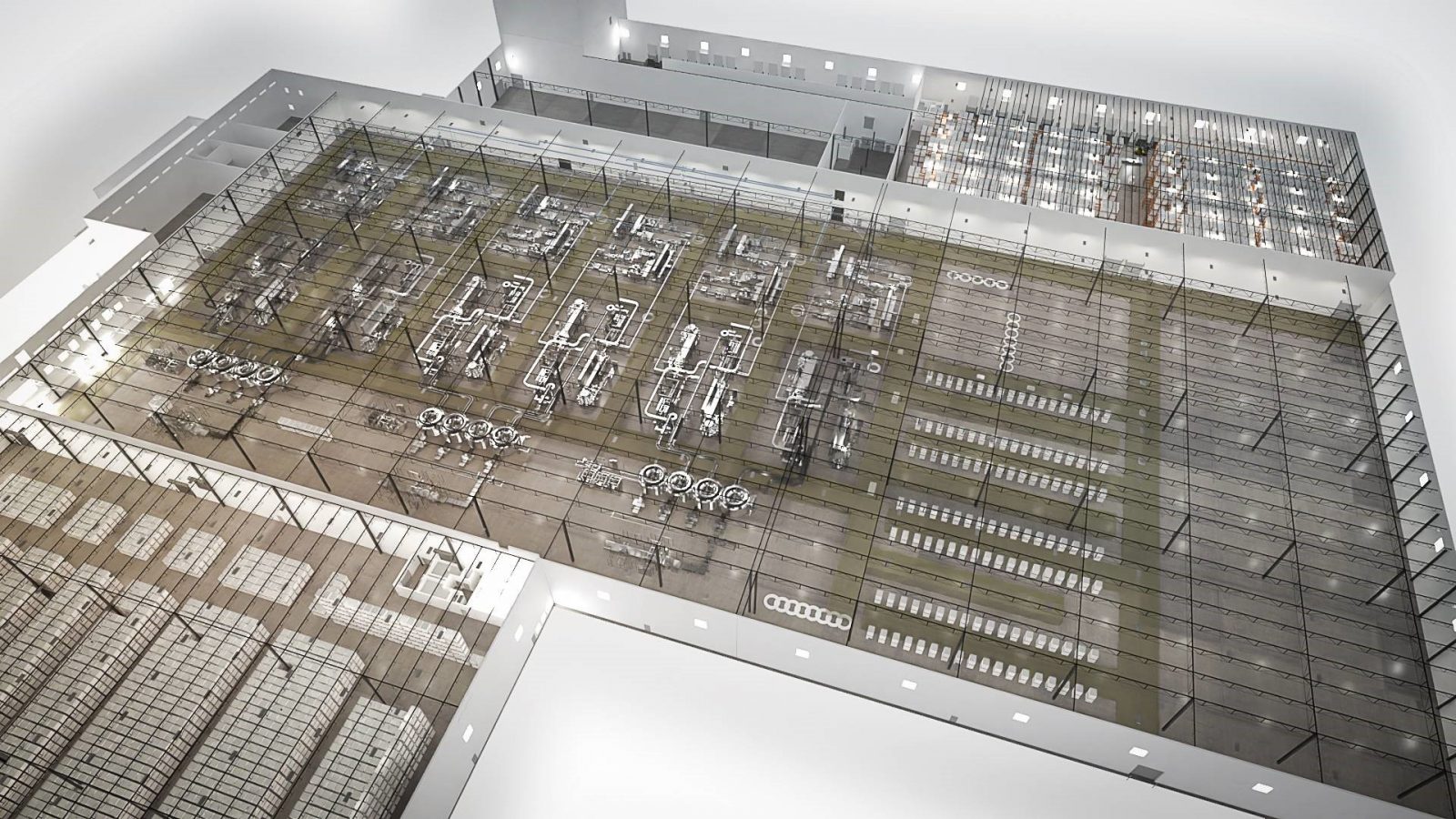

At the forefront of operational transformation, KPI Solutions specializes in blending best-of-breed technology to enhance the efficiency of storage, conveyance, and order fulfillment processes within the protein industry.

By providing a comprehensive suite of automated systems, intelligent software solutions, and dedicated lifetime services, we cater to your business’s specific requirements. Coupled with our consulting services, we empower you to streamline your operations, tackle distribution challenges head-on, and secure a competitive advantage in the marketplace.

Current Challenges in Protein Distribution

The protein industry faces several key challenges that directly impact efficiency, sustainability, and customer satisfaction. From managing a skilled workforce to navigating the complexities of direct-to-consumer (DTC) fulfillment, these challenges require innovative and strategic solutions.

-

Labor Efficiency & Turnover: The food distribution sector grapples with optimizing labor efficiency while also facing high turnover rates. This dual challenge necessitates not only attracting and retaining skilled workers but also implementing processes and technologies that enhance productivity and reduce dependency on manual labor.

-

Rising Energy Costs: As costs associated with operating a temperature-controlled operation continue to climb, protein distribution operations must find ways to reduce energy consumption without compromising product quality.

-

Inventory Management: Striking the right balance in inventory levels to meet the ebb and flow of demand is particularly challenging in the protein industry, where product perishability limits shelf life. Advanced inventory management systems that forecast demand and optimize stock levels are crucial to minimize waste and avoid stockouts.

-

DTC Order Fulfillment: The surge in e-commerce and direct-to-consumer sales channels introduces complexities in order fulfillment, requiring protein distributors to adapt their picking, packing, and shipping processes. Tailoring logistics for individual orders demands flexibility and precision to meet consumer expectations for customization and on-time delivery.

Build a Robust Strategy for Your Business

At KPI Solutions, our goal is to provide clients with the analytical, engineering, and operations expertise necessary to achieve business goals. Whether you need data-driven consulting services or a comprehensive material handling system to grow your meat distribution business, partnering with KPI Solutions equates to aligning with a team dedicated to your business’s ever-changing business demands.

Creekstone Farms Premium Beef

KPI Solutions worked with Creekstone Farms to design and implement an automated single-box cold storage facility for their boxed beef distribution center that is achieving downtime results unheard of before.

“The automation takes care of the hard work.”

– Satisfied Food Industry Client

Why Partner with KPI Solutions to Optimize your Operation?

-

Proven Experience: We conduct an independent analysis to determine the most suitable solution.

-

Expert Guidance: Our team of experienced consultants offers objective advice.

-

A Commitment to Your Growth: Partnering with KPI Solutions equates to aligning with a team dedicated to your business’s expansion.

Trusted for Supply Chain Logistics and Protein Warehouse Automation

Ensure accuracy

Support durability

Improve your warehouse logistics

Enhance your warehouse management system

Improve supply chain management

Update industrial automation

Become more competitive

Automated Material Handling & Storage Systems for the Protein Industry

KPI Solutions delivers best-of-breed automated technology to streamline meat protein operations. Unlike traditional manufacturers, our approach is to analyze your specific challenges and objectives, then tailor a combination of the best available systems to streamline your operational processes.

Our comprehensive suite includes AS/RS to manage inventory with precision, conveyor and sortation systems for efficient material flow, and automated palletizing and stretch wrapping for expedited end-of-line processes. Integrated with Opto™ software, our solutions offer a reliable and scalable approach to enhance operational efficiency and order fulfillment.

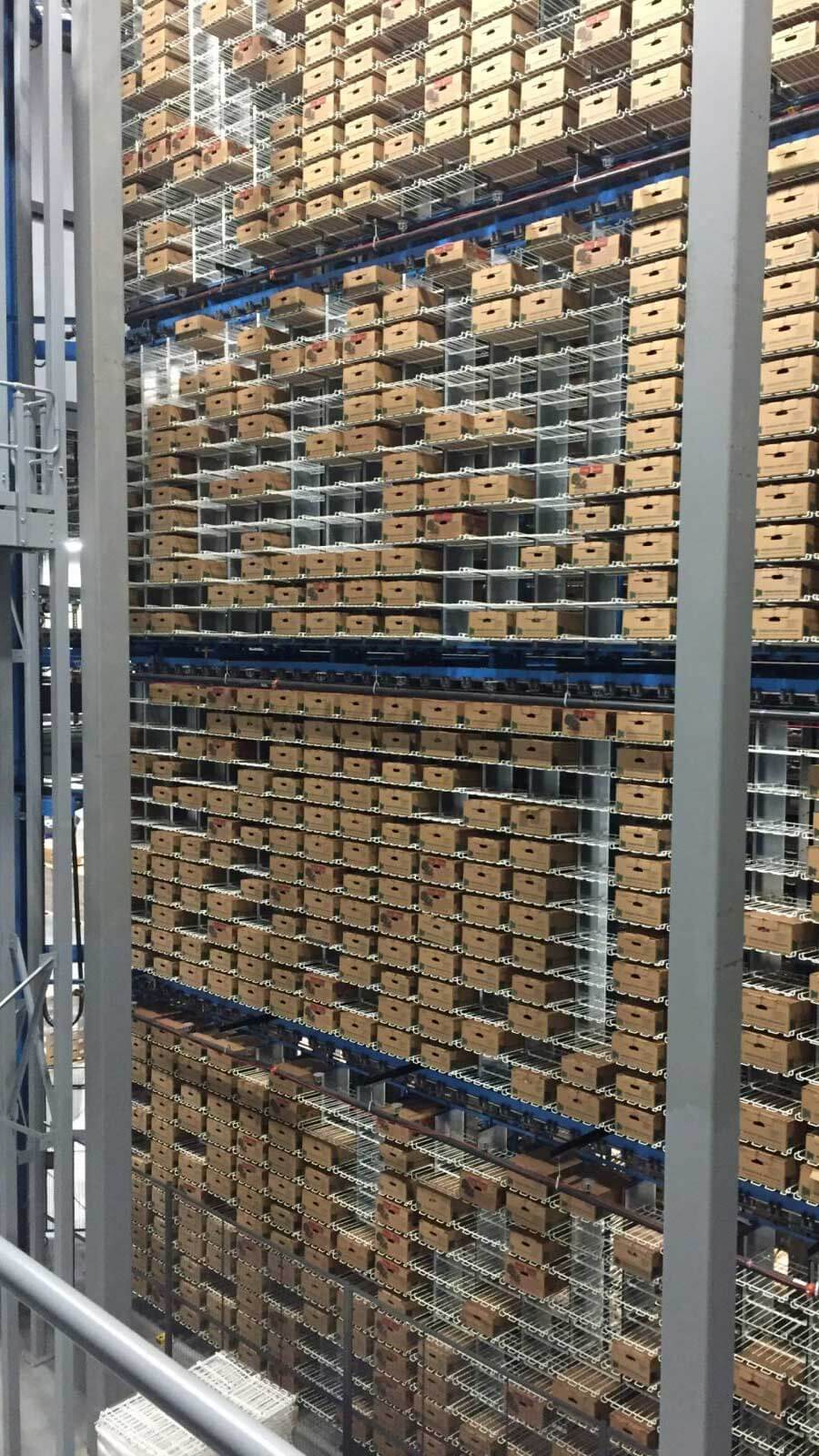

Automated Storage and Retrieval Systems

Transform your meat protein distribution with Automated Storage and Retrieval Systems (AS/RS) tailored to your specific operational needs. Specializing in the integration of Horizontal Carousels for boxed beef and crane-based AS/RS for full pallet loads, we provide solutions that enhance storage density, inventory accuracy, and order processing speed.

- Horizontal Carousels: For rapid access and reduced picking times of boxed beef.

- Crane-based AS/RS: To maximize vertical storage and automate pallet handling.

- Seamless Integration: Our expertise ensures your system enhances workflow and scales with your business.

Conveyor & Sortation Systems

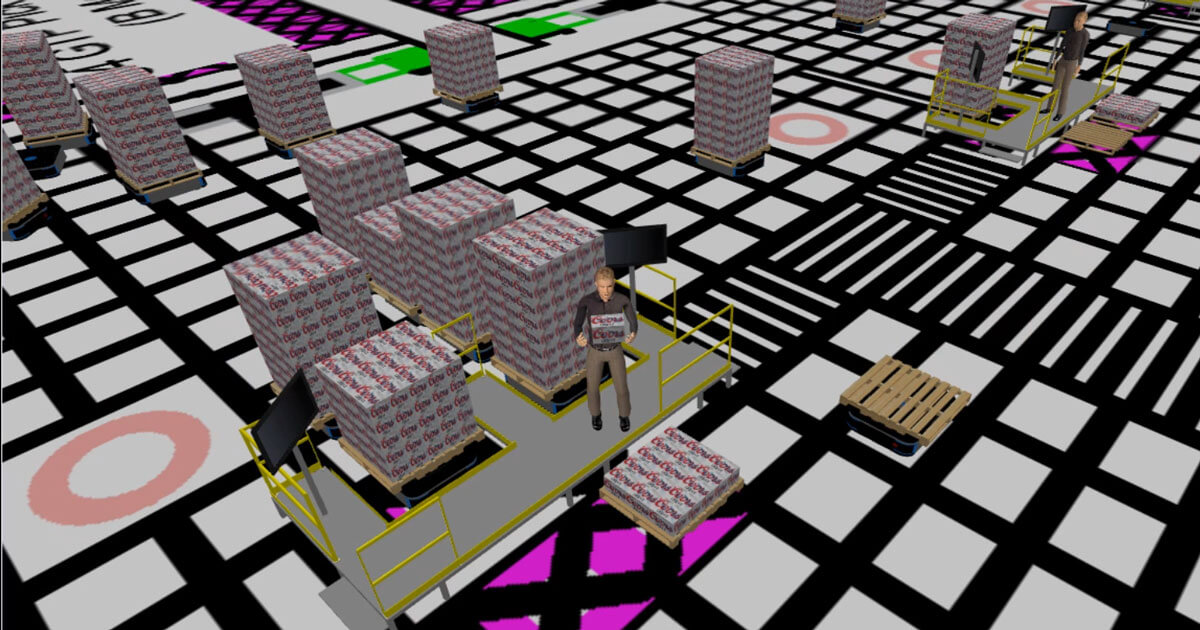

Expertly designed systems to efficiently move inventory throughout your operation, reducing manual handling and optimizing throughput.

- Strategic Material Flow: Utilizing powered conveyors and advanced sorters for swift, efficient inventory movement.

- Optimized Sortation: Incorporating high-speed shoe sorters and storage buffer sortation to precisely route products and reduce handling time.

- Efficient Processing: Employing accumulation lanes for seamless processing, ensuring continuous throughput with minimal delays.

Automated Palletizing

Leverage the power of the latest palletizing technology for improved efficiency and accuracy in the pallet building process. By optimizing every aspect of palletization, you can realize faster, more reliable order fulfillment.

- Versatile Packaging Compatibility: Adapts to a wide range of package types and sizes, ensuring flexibility across your product lines.

- Customized Stack Patterns: Tailors pallet stacking strategies to meet specific order requirements, optimizing space utilization and load stability.

- Enhanced Throughput and Accuracy: Increases the speed and precision of the palletizing process, streamlining order fulfillment and minimizing manual errors.

Rotary Stretch Wrapping

Ensure the stability and integrity of your palletized products with automatic, high-speed rotary stretch wrappers. Designed for rapid and reliable load securing, they are essential for maintaining the quality of your products during transit.

- Consistent Application: Automated and precise film application ensures consistent wrapping for pallet load stability.

- Efficiency at Speed: Capable of wrapping numerous pallets per hour to maintain pace with your high throughput demands.

- Reduced Material Waste: Optimized film usage reduces waste and operational costs, contributing to a more sustainable packaging process.

Opto™ Software

Streamline your meat protein operations with Opto™ Software, our proprietary suite designed for seamless warehouse and distribution management.

- Real-Time Operations Insight: Gain clear visibility and actionable analytics with Opto Control Tower, driving smarter, faster decision-making.

- Adaptable Execution System: Opto WES adapts to your facility’s needs, enhancing workflow and resource management for peak productivity.

- Unified Control System: Opto Connect ensures smooth communication between various systems, centralizing control for operational efficiency.

LifeTime Services

We provide planning, support, and maintenance to ensure your system will remain functioning as designed, enabling you to confidently focus on achieving your business goals. Our LifeTime Services are modular, scalable, and easily customized to create the right package for you.

- 24/7 Support

- Field Services

- Resident Maintenance

- Parts & Warranty

More Efficient, More Competitive

- While supply chain management in the protein industry can produce immense challenges, we understand that it’s of utmost importance.

- From farm to market, each step in the protein supply chain should be closely monitored for safety and efficiency.

- The more effective and efficient your protein warehouse automation solutions, the more opportunities you have for profitability.

- When each partner in the supply chain is held accountable for focusing on their core competencies, business thrives.