This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Optimizing Performance in Manufacturing Operations

In manufacturing fulfillment, where process optimization directly influences competitiveness, automation emerges as a pivotal tool for eliminating inefficiencies and fostering lean operations. KPI Solutions leverages in-depth data analysis and strategic planning to integrate automation into your processes, minimizing disruption and setting the stage for continuous growth. With extensive industry experience and access to premier technology, we’re equipped to transform your manufacturing environment, ensuring your operations are streamlined for current challenges and future opportunities.

Current Challenges for Manufacturers

Adapting to market demands, managing rising labor costs, navigating SKU proliferation, and ensuring operational efficiency highlight the complex landscape that manufacturers navigate.

As your partner, we focus on addressing these challenges by optimizing floor space usage, implementing just-in-time delivery, enhancing material flow, improving labor ergonomics, and maximizing system uptime to meet your production requirements.

-

Adapting to Market Demands: Manufacturers must quickly adjust to market changes using just-in-time (JIT) systems to avoid stockouts or overproduction, ensuring optimal inventory turnover.

-

Rising Labor Costs: With skilled labor becoming costlier, automation becomes crucial for maintaining operational efficiency and throughput, while adhering to total quality management (TQM) principles.

-

SKU Proliferation: Facing consumer demands for variety, manufacturers need flexible production lines capable of managing diverse SKUs efficiently, without sacrificing production speed or quality.

-

Operational Efficiency: Emphasizing lean manufacturing fulfillment processes, operational efficiency involves streamlining processes to reduce waste and increase productivity, with a focus on effective space utilization and process optimization.

Successful Manufacturing Operations

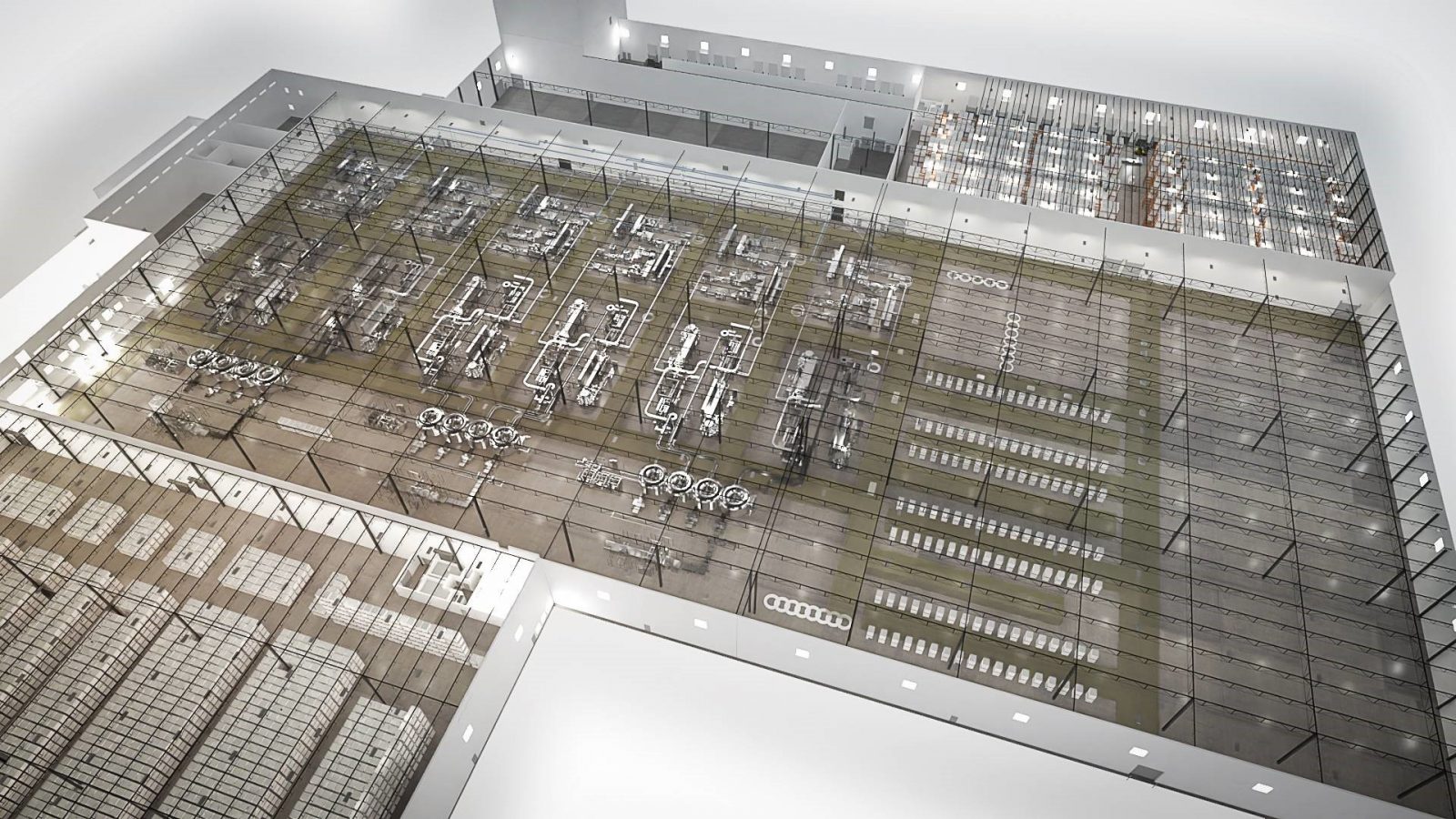

Transform manufacturing operations and parts storage with AutoStore, a leading automated storage and retrieval system (AS/RS). Designed for efficiency and scalability, AutoStore optimizes space, boosts fulfillment speed for needed components, and reduces labor requirements.

With updated material handling solutions you can increase your company’s efficiency and benefit your partners as well as your clients.

Automated Material Handling & Storage Systems for the Manufacturing Operations

At KPI Solutions, we integrate custom-engineered automation solutions tailored to meet the exact needs of your manufacturing operation. Our focus is on specific areas where automation can bring the most value—enhancing material handling with scalable AMRs & AGVs, streamlining storage with high-density AS/RS and pallet racking systems, and optimizing end-of-line processes with conveyor systems, automated palletizing, and high-speed stretch wrapping.

Central to our approach is the integration of Opto™ software, providing critical operational insights and control, ensuring each solution is precisely aligned with your operational goals. With our comprehensive LifeTime Services, we support the longevity of your system with field services, resident maintenance, and spare parts programs.

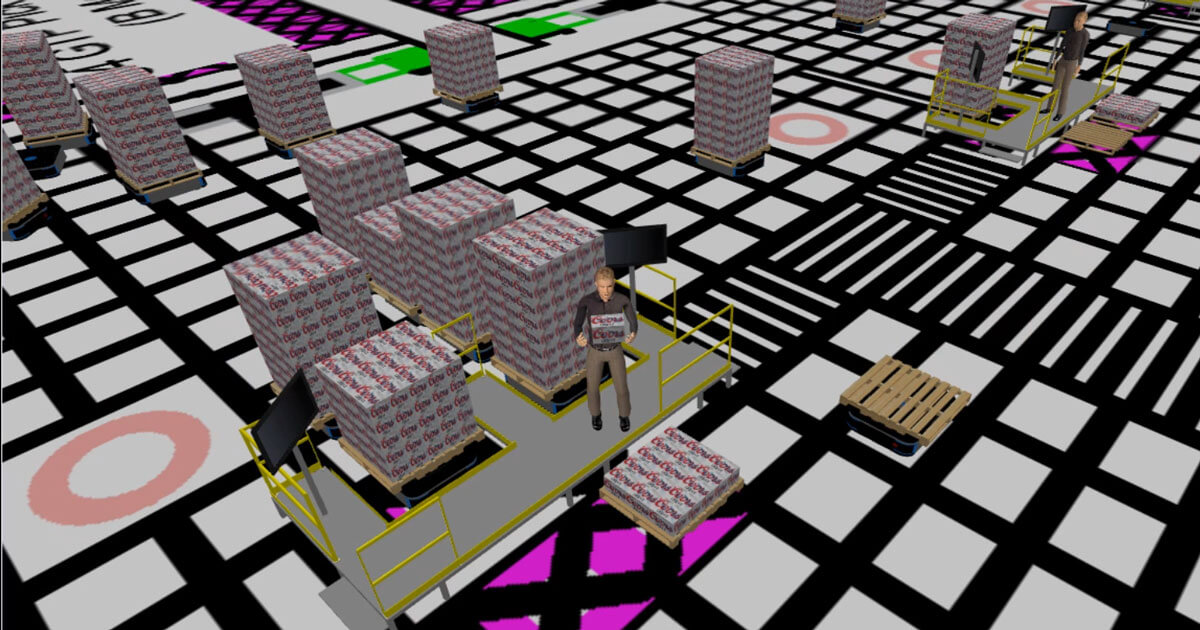

AMRs & AGVs

Adaptive automated systems to support various repetitive and labor-intensive tasks within a production environment, such as:

- Kitting

- Handling of Pallets, Bins, and WIP

- Management of Packaging Materials

- Order Staging

Automated Storage and Retrieval Systems

Optimize your manufacturing operations with AS/RS, an innovative solution that addresses key challenges in inventory management and storage efficiency. These systems can enhance the precision and speed of accessing spare parts and managing buffer inventory, directly supporting lean manufacturing and just-in-time (JIT) production strategies.

Conveyor Systems for Manufacturing

Custom-engineered conveyor solutions to automate product flow from production to packaging, enhancing efficiency and minimizing manual intervention.

Automated Palletizing

Harness advanced palletizing solutions to elevate the efficiency and precision of your end-of-line processes. Through automation, streamlined pallet building accelerates product dispatch while ensuring accuracy and stability.

Rotary Stretch Wrapping

Ensure the stability and integrity of palletized products with automatic, high-speed rotary stretch wrappers.

- Consistent Application: Automated and precise film application ensures consistent wrapping for pallet load stability.

- Efficiency at Speed: Capable of wrapping numerous pallets per hour to maintain pace with your high throughput demands.

Opto™ Software

Streamline your manufacturing operations with Opto™ Software:

- Real-Time Operations Insight: Gain clear visibility and actionable analytics with Opto Control Tower, driving smarter, faster decision-making.

- Adaptable Execution System: Opto WES adapts to your facility’s needs, enhancing workflow and resource management for peak productivity.

- Unified Control System: Opto Connect ensures smooth communication between various systems, centralizing control for operational efficiency.

LifeTime Services

We provide planning, support, and maintenance to ensure your system will remain functioning as designed, enabling you to confidently focus on achieving your business goals. Our LifeTime Services are modular, scalable, and easily customized to create the right package for you.

- 24/7 Support

- Field Services

- Resident Maintenance

- Parts & Warranty

Pallet Racking Systems

- Optimized Storage Density: Maximize floor space by vertically stacking materials, allowing for greater inventory capacity within the same footprint.

- Enhanced Accessibility: Ensure quick and easy access to materials and products, streamlining the picking process and reducing retrieval times.

- Customizable Configurations: Tailor your storage setup to meet specific operational needs, accommodating various pallet sizes and weights for optimal organization and efficiency.